Laser cutting has become a key process in today’s metal industry. Work that would have taken days or even months a few years ago can be done in outstanding quality and at incredible speeds. We provide our customers with precise technologies and innovative processes that save time and energy for them in the manufacturing of their products. With 3D laser cutting, even the most complex and creative shapes can be cut with a precision of a hundredth of a millimetre, while planar laser cutting allows workpieces to be cut quickly and in large quantities. Because treatment is solely based on the CAD file, the customer’s ideas are directly translated into the finished product.

In laser engraving, a concentrated laser beam causes the material to evaporate or burn. It can be used to create highly durable, highly visible and legible lettering, logos, images, serial numbers or even barcodes on almost any material. It can be used in very wide range of applications. In industry, engraving can be used to brand various tools or provide tools or parts with sequence numbers. Thanks to the properties of the laser beam, it is possible to engrave on tiny surfaces with high precision. The YAG (yttrium-aluminium-garnet) laser is a laser light with variable frequency and intensity, whose movement is controlled by a mirror. It burns the image to be engraved into the surface with micrometre precision. Thanks to its variable frequency and intensity, it can mark a wide range of materials: metal, plastic, stained wood, leather and leatherette.

From a technological point of view, a CNC machine tool is a programmable, flexible, automatically operating production machine. Its most important feature is its great flexibility as, thanks to the programs stored in the control unit, it can be used for a very wide range of machining tasks. Furthermore, the changeover time of CNC machine tools between the machining of workpieces with different geometries is very short as the launch of a new programming task merely consists of loading and running the program written for the relevant task (and, in some cases, changing a few tools).

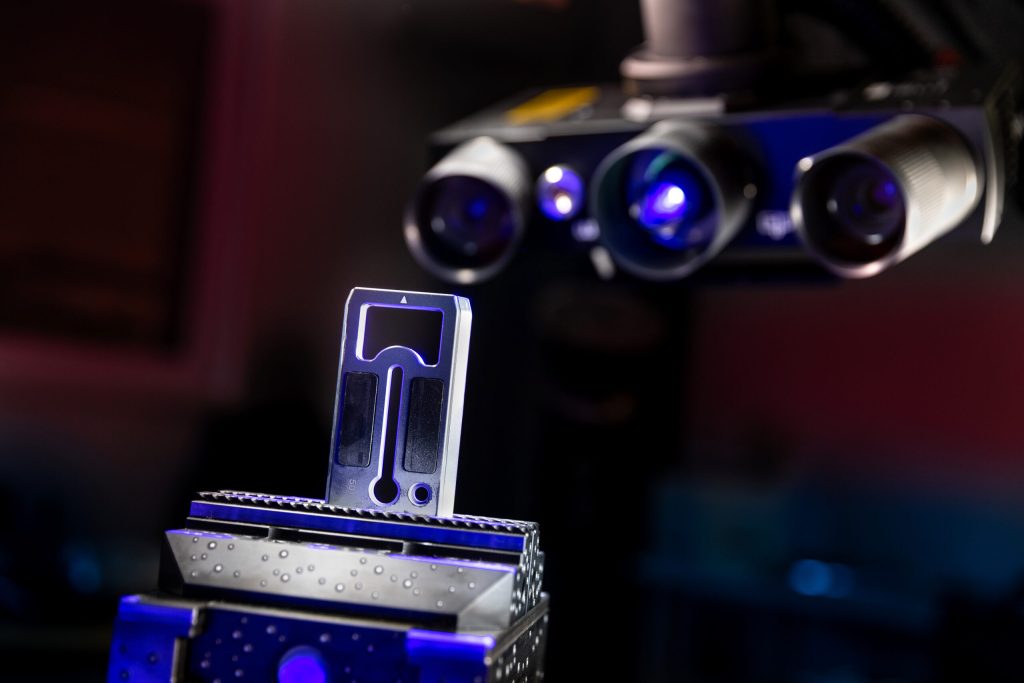

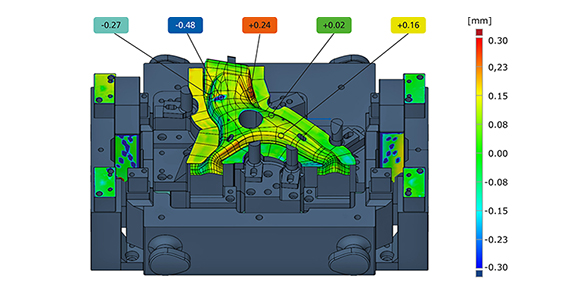

Our company group uses the non-contact optical measuring systems of GOM to provide 3D metrology services, 3D digitizing (3D scanning), evaluation, quality control and supplier screening for our partners. Measuring instruments can be used in a wide range of applications without industry-specific restrictions, including:

The ATOS product range from GOM consists of optical 3D coordinate measuring systems enabling the full-surface, non-contact measurement of prototypes, electrodes, tools and injection-moulded components, regardless of geometry and object size. In contrast to tactile measuring methods, which apply a measuring force to the piece and may cause deformation, and the number of points recorded is also lower, the optical method records even complex free surfaces quickly and in a completely contact-free manner. In our measurement laboratory, we can carry out automated measurements within a short time, even in large series. In addition to 3D measuring systems, we also have manual measuring instruments (ultrasonic hardness testers, surface roughness testers, layer thickness meters, measuring blocks, etc.) to support the repair and manufacturing processes carried out in our workshop.

During the process, we reconstruct the fracture, damage, wear, defect by means of laser welding or cladding, and then our toolmakers manually rework the surface in conformity with the model using continuous 3D scanning. The repair is therefore quick and does not require extremely costly logistics. Furthermore, the process can be fully tracked and documented thanks to the GOM scanners. In any case, we will provide the Customer with a repair report, in which model conformity can be graphically demonstrated. If no technical documentation is available for the piece to be repaired, we can also reverse engineer the model.

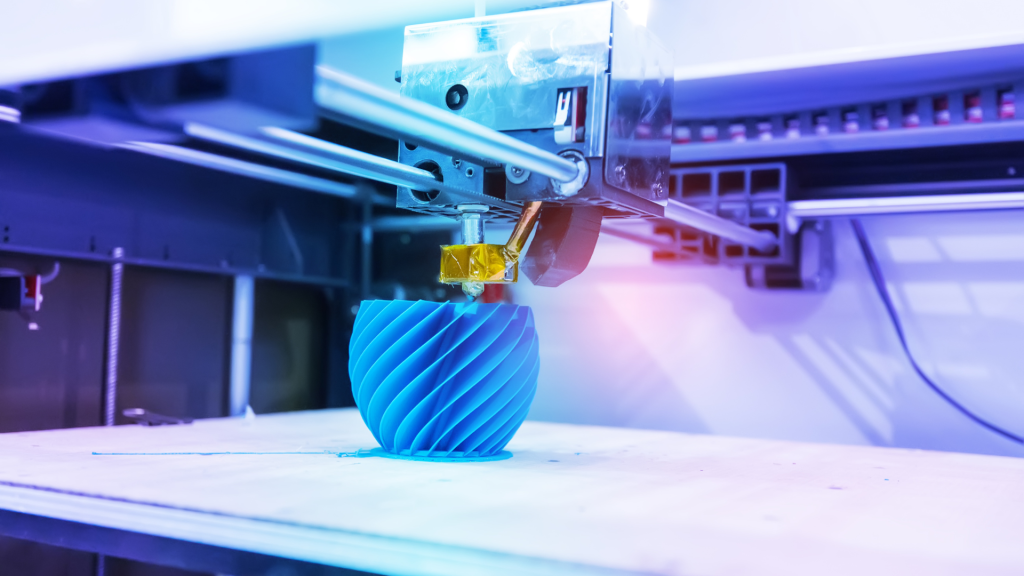

Fused Wire Deposition, also known as FDM technology, is a patented additive manufacturing process from industry leader Stratasys. The technology is suitable for the production of concept models, functional prototypes and direct-use components made of high-performance thermoplastic engineering plastics.

FDM technology can be used to produce components from the same strong plastics used in injection moulding and other traditional manufacturing processes.

The technology can be applied to product manufacturing and the production of service components and parts for several industries, such as:

With the Stratasys Fortus models we use, we can 3D print using the material that best suits the application. We work with ASA, ABS, PC, PC-ISO, PC-ABS, FDM Nylon and ULTEM materials according to requirements set by the customers or the printed parts. Thanks to GOM optical scanners, we can create the product models required for 3D printing in our strategic partner’s lab, based on a sample piece or a drawing. If it is more optimal to manufacture the part by machining, we also do it in our own workshop with our own tools, using the material chosen according to the application (POM, PEEK, PEKK, PA66, etc.).

The purpose of reverse engineering is to replace incomplete or missing technical documentation, or to create it on the basis of an existing object. During the process, the piece (be it a product or a tool part) is digitised (digitally copied) using a GOM scanner, and then, based on the digitised file, production documentation (CAD model, shop drawing) is created.

During reverse engineering, high-resolution GOM scanners are used to create highly accurate technical documentation based on the existing object. On the basis of the completed production and technical documentation, we produce custom and small-series parts by 3D printing or machining.

We offer our customers a design collaboration service, enabling them to implement optimised and efficient processes in production. Our experienced colleagues develop solutions tailored to the needs of our customers, taking into account engineering and materials technology aspects to ensure high quality and accurate implementation. Our design service makes it easy for customers to meet specific requirements and execute individual projects.

Sheet bending and profile bending are sheet forming processes resulting in permanent deformation, used to bend steel and aluminium sheets, tubes and steel profiles to shape. During the sheet bending process, processing is performed based on a computer program, and the stops are automatically set to a predefined position. This allows several different bending operations to be performed in succession.

Ask for an individual offer!

A special service of our company, unique in Hungary and the surrounding countries, is that we can perform laser hardening and cladding at the customer's site.

2024 © APZ Laser Kft.

Dear Visitors!

Our company will be closed between 21 December 2024 and 6 January 2025.

Thank you for your understanding, we wish you happy holidays and a happy new year!